How Can SAP DMC Help Your Business: 5 Best Solutions

SAP DMC is an abbreviation for SAP Digital Manufacturing Cloud. It refers to the software solution provided by SAP that helps manufacturing companies optimize their manufacturing operations through digital technologies.

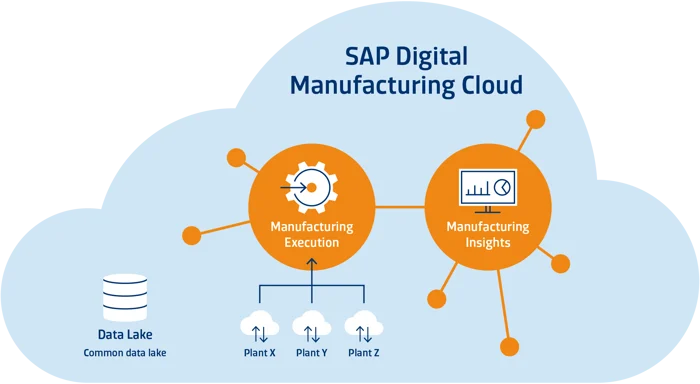

SAP Digital Manufacturing Cloud

SAP Digital Manufacturing Cloud (SAP DMC) is a cloud-native solution designed to streamline manufacturing processes, manage production orders, and analyze various scenarios. It aims to support production supervisors and workers in optimizing processes and effectively distributing workloads.

SAP DMC is well-suited for organizations with multiple branches and operations in different countries and regions. This solution offers real-time analytics and business insights for individual branches as well as the entire company, enabling informed decision-making and enhanced operational performance.

The SAP Digital Manufacturing Cloud (SAP DMC )provides a range of features and capabilities to support various aspects of the manufacturing process. Some key features include:

- Manufacturing Execution System (MES): The MES functionality helps manufacturers manage and control shop floor operations in real time. It enables operators to track production orders, monitor equipment status, record production data, and enforce quality control measures.

- Shop Floor Connectivity: The solution facilitates connectivity between machines, sensors, and other shop floor devices, allowing real-time data collection and communication. This helps in capturing and analyzing data from the production line for better decision-making and process improvement.

- Manufacturing Analytics: SAP Digital Manufacturing Cloud (SAP DMC) provides analytics and reporting capabilities to help manufacturers gain insights into their operations. It includes dashboards, key performance indicators (KPIs), and advanced analytics for monitoring production efficiency, identifying bottlenecks, and optimizing overall equipment effectiveness (OEE).

- Integrated Quality Management: The solution includes quality management features to ensure product quality and compliance. It helps in tracking and managing quality data, conducting inspections, managing non-conformances, and facilitating corrective and preventive actions.

- Digital Twin Integration: SAP Digital Manufacturing Cloud can integrate with digital twin technology, which creates a virtual representation of physical assets and processes. This integration enables manufacturers to simulate and optimize production scenarios, predict outcomes, and perform what-if analyses.

By leveraging these features, SAP Digital Manufacturing Cloud aims to improve operational efficiency, reduce costs, increase product quality, and enhance overall manufacturing performance. It provides a digital platform for manufacturers to digitize and transform their operations, enabling them to stay competitive in today’s rapidly evolving manufacturing landscape.

SAP DMC Features

1. Purposeful and meaningful data

- S88 Production Model:

The S88 production model, also known as the ISA-88 standard, provides a structured framework for designing and controlling batch processes in manufacturing. It defines standardized models and terminology for defining and managing recipes, units, equipment modules, and control strategies.

- S95 Production Model:

The S95 production model, or the ISA-95 standard, focuses on the integration of enterprise and control systems. It provides a standardized approach for mapping business processes to control systems, enabling seamless information flow between different levels of the manufacturing organization.

- Control System and Operational Event Mapping:

The SAP Digital Manufacturing solution facilitates the mapping of control systems and operational events. It allows for the integration of various control systems, such as programmable logic controllers (PLCs) or distributed control systems (DCS), with the overall manufacturing process. Operational events, such as equipment status changes or production order updates, can be captured and synchronized across the manufacturing ecosystem.

- Analytics and Self-Service Reports:

The SAP Digital Manufacturing solution offers analytics capabilities to analyze production data and generate key performance indicators (KPIs). It allows users to create self-service reports and interactive dashboards to visualize and monitor live operational data. This enables better decision-making and real-time insights into manufacturing performance.

- KPIs and Live Operations Data:

The solution enables the tracking and measurement of KPIs related to manufacturing operations. It provides access to live operations data, including production rates, quality metrics, equipment utilization, and downtime analysis. Users can leverage this data to monitor performance, identify bottlenecks, and drive continuous improvement initiatives.

2. Harmonized, reliable analytics

- Data Acquisition from Disparate Manufacturing Systems:

The SAP Digital Manufacturing solution allows for the acquisition of data from various manufacturing systems that may be operating independently or using different technologies. It provides the capability to gather data from diverse sources such as PLCs, DCS, SCADA, and other proprietary systems.

- Blending Manufacturing Data with SAP S/4HANA and SAP ERP:

The solution (SAP DMC) facilitates the integration and blending of manufacturing data with SAP S/4HANA and SAP ERP systems. This integration enables a unified view of manufacturing operations, combining real-time data from the shop floor with core business processes such as inventory management, procurement, and production planning.

- Integration with MES Systems:

The SAP Digital Manufacturing solution seamlessly integrates with MES systems, specifically SAP Manufacturing Execution and SAP Manufacturing Integration and Intelligence. This integration enables the synchronization of data and processes across different manufacturing layers, ensuring a seamless flow of information from the shop floor to the enterprise level.

- SAP Manufacturing Execution:

The integration with SAP Manufacturing Execution (SAP ME) allows for real-time visibility into shop floor operations, including work orders, resource allocation, production tracking, and quality management. It enables the efficient execution of manufacturing processes and provides a comprehensive set of tools for managing and monitoring production activities.

- SAP Manufacturing Integration and Intelligence:

The integration with SAP Manufacturing Integration and Intelligence (SAP MII) enables the collection, transformation, and analysis of manufacturing data from multiple sources. It provides advanced analytics capabilities to gain insights into production performance, optimize processes, and support decision-making.

3. Unified manufacturing modeling

- Building on Industry Standards:

The SAP Digital Manufacturing solution is built on top of industry standards, ensuring compatibility and interoperability with existing technologies and systems commonly used in the manufacturing industry.

- KPI Definition with Modeling Environment:

The solution provides a modeling environment that allows users to define Key Performance Indicators (KPIs) according to their specific manufacturing requirements. This enables organizations to customize and tailor KPIs to their unique business needs.

- Harmonized Data Model:

The SAP Digital Manufacturing solution utilizes a harmonized data model, which provides a standardized structure for organizing and storing manufacturing data. This promotes consistency and facilitates the seamless integration of data across different systems and processes.

- Application of Integration Standards:

The solution applies existing and predetermined integration standards to ensure smooth integration with various systems and technologies. These integration standards help streamline data exchange, communication protocols, and interfaces between different components of the manufacturing ecosystem.

4. Predefined industry standards

- Using Preconfigured Industry-Standard Manufacturing KPIs:

The SAP Digital Manufacturing solution offers preconfigured industry-standard Key Performance Indicators (KPIs) that organizations can readily leverage for measuring and evaluating manufacturing performance. These KPIs are based on best practices and widely accepted benchmarks within the manufacturing industry.

-

Building KPIs from Existing Enterprise and MOM Systems:

The solution enables the creation of KPIs based on the organization’s existing enterprise systems and Manufacturing Operations Management (MOM) systems. It leverages data from these systems to develop KPIs that align with the specific manufacturing processes and objectives of the organization.

SAP Manufacturing Execution