To establish the strength and deformation behavior of material up to the point of fracture, a tensile tester or tensile testing machine is used. The material to be tested and the standard(s) that must be followed will determine which tensile testing machine is best.

Table of Contents:

- What is a Tensile Tester?

- What is Automated tensile testing and its benefits:

- Types of universal testing machine

- (5) Best Tensile Testing Machine Manufacturers:

- FAQs

What is a Tensile Tester?

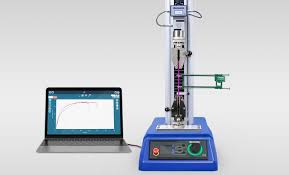

A load cell, crosshead, extensometer, specimen grips, electronics, and a motor system make up a standard tensile testing apparatus. It is managed by testing software that stores test parameters established by testing standards like ASTM and ISO and defines machine and safety settings.

Throughout the test, the machine’s force and the specimen’s length are measured and recorded. Designers and manufacturers can forecast how materials will function when used for their intended purpose by measuring the force necessary to stretch or elongate a material to the point of permanent distortion or break.

What is a Tensile Test?

A tensile test, also known as a tension test, is a procedure used to ascertain how a material will respond to a pulling force. Ultimate tensile strength, maximum elongation, and area reduction are characteristics that are directly measured during a tensile test. Young’s modulus of elasticity, Poisson’s ratio of deformation, yield strength, and strain-hardening characteristics can all be calculated from these measurements.

- Ultimate tensile strength -the highest tensile stress that a material is capable of withstanding before failing.

- Maximum elongation – The greatest strain that a material can withstand before failing

- Reduction in the area – It serves as a gauge to demonstrate how much a material will flex under a tensile force.

Who is for the tensile test?

Tensile testing application examples include:

Tensile testers are used to assess the durability of components, finished goods, and material qualities. Objects including cloth fasteners, welded connectors and fastenings, adhesive joints, and seals are frequently subjected to tensile testing.

Examples:

- Plastic packaging

- Concrete-reinforcing steel bars

- Rubber compounds for use in tires

What qualities should I consider while selecting a Tensile Testing Machine?

Many other elements should be taken into account when picking your machine, in addition to quality, test result dependability, cost, and application:

Flexibility – means being able to test a variety of materials in a wide load range, integrating and switching between attachments that are specially made for different industry standards, types of material, and applications, and having the choice of running the machine with or without a PC.

Safety – The tensile tester’s safety is crucial, and it goes beyond the usage of physical safety measures like exterior safety doors, safety enclosures, safety interlocks, and limit switches to include human management and software system monitoring.

Ease of use – The goal is to find a testing system that is both operable and smart in design in terms of ease of use.

Adaptability – Make sure your machine can adapt to these changes, from accessories and fixtures to electronics and software applications, before choosing a tensile tester. E – The most important thing is to pick a testing system that is both operable and complex in design.

Software – for testing is designed to facilitate the operator’s testing procedure and guarantee uniform and standard-compliant test setups.

Standards library – For tests that go above and beyond the norm or for the freedom to fully configure your machine’s test sequence.

Automation – Testing methodologies span from effective small-series test automation using cooperative lab robots to completely automated testing facilities operating around the clock.

How to Buy the Best Value Tensile Testing Machines:

Select from ten different frames and two different technologies with hundreds of variations to maximize your testing possibilities.

This implies that you receive a system that is precise, meets your requirements and is within your price range. Fewer sacrifices result from more options.

For tensile testing with forces up to 300 kN, electromechanical test equipment is the best option (112 kips). The ideal configurations for electrohydraulic test machines are those with high load capabilities between 300 kN (112 kips) and 2000 kN. (450 kips).

(3) Simple Steps to Select Your Tensile Test Machine:

Select your frame:

Determining the specimen’s geometry, size, and strength properties is the first step in selecting the ideal tension tester. Choosing the test data you want to collect will help establish which controller and test software are best for your test, which is the next step.

Start by Selecting a Series:

- 100 Series Modular Tensile Test Machines:

Type: Electromechanical

Force: 9 kN (2,000 lbf)

- 200 Series Single Column Tensile Test Machines:

Type: Electromechanical

Force: 5 kN (1,125 lbf)

- 300 Series High Force Tensile Test Machines:

Type: Electromechanical

Force: 300 kN (112 kip)

- About 600 Series High Force Hydraulic Tensile Test Machines

Type: Hydraulic

Force: 2 MN (450 kip)

When high force capacity is required, such as when evaluating metals and metal goods, the best 600-Series High Force Hydraulic Tensile Test Machines are the ideal option. Test equipment from the 600 Series has capabilities ranging from 300 kN to 2 MN (67,500 lbs and 450 kips).

Best Tensile Test Grips & Fixtures Options:

Tensile Test Fixtures:

- Wedge grips – See mechanical, pneumatic, and hydraulic options

- Vice grips – See mechanical, pneumatic, and hydraulic options

- Options for mechanical, pneumatic, and hydraulic wire and cable capstan grips

- Threaded and buttoned metal sample holders

- Webbing, strapping, and sheet grips

Tensile Test Machine Controls & Software:

The test apparatus has a closed-loop servo controller with user-selectable control modes, including constant load rate (lbs per minute), constant strain rate, constant velocity, or rate of grip separation (crosshead displacement).

When doing service load tests, it may be necessary to use an additional TestCreator module that enables the automation of up to 255 distinct stages in some applications.

Tensile Force & Strain Measurement Sensors:

Each testing device has at least one force channel designated to a load cell, and the load cell is calibrated in accordance with industry norms like ASTM E4 or ISO 7500-1. Additionally, signal conditioning channels are assigned to one or each of the three strain measurement sensors previously described. In order to calculate stress-strain curves, this data is collected with sample dimensions.

- E3542 Clip on Axial Extensometer

- E3540 Deflectometer

Types of Tensile Testing Machines:

What are the typical components of a tensile testing machine?

What is Automated Tensile Testing and its benefits:

Tensile Strength Testing Equipment

Industry standards like ASTM, ISO, TAPPI, and other top-quality organizations specify the test procedure in order to measure the material’s overall strength and the extent of its deformation under stress.

A typical tensile testing machine is made up of a few fundamental parts. These test frames primarily consist of a load cell, crosshead, grips, electronics, and a drive system. Testing software is used to manage the apparatus and analyze machine and safety settings as well as compare sample performance to test parameters specified by testing standards.

A tensile test is used to assess performance in a controlled testing environment and identify how a material will respond to an applied force. The test frame has grips and fasteners to hold the sample while performing the required test to find out a number of characteristics, including yield strength, tensile strength, strain at break, and extra material qualities including elasticity and deformation properties. The test’s output data is typically presented on a graph and displays real-world performance characteristics.

QC-3A Universal Testing Machine: Measurements of qualities including compression, coefficient of friction (COF), peel analysis, and more are precise thanks to the QC-3A Universal Testing Machine.

VantageNX Tensile Testing Machine: One of the most complete tensile testers on the market is the VantageNX Tensile Testing Machine. The capacity of the five different frame tester models ranges from 1kN and 225 pounds of force to 10kN and 2,000 pounds of force.

(5) Best Tensile Testing Machine Manufacturers:

A tensile force is applied to raw materials by an electromechanical testing instrument known as a Universal Testing Machine (UTM), sometimes known as a tensile testing machine or tester or components to test for both tensile and compressive strength.

1). Shimadzu:

For more than a century, Shimadzu has been a leader in the production of high-quality material testing equipment. Shimadzu offers a wide range of products to conduct static testing, including tensile, compression, bend, peel, tear, shear, friction, piercing, and other mechanical tests.

The AGX-V series flagship model, the industry’s best-performing autograph precision universal tester, the AGS-X series autograph table-top precision universal tester, combines all necessary testing functions with a compact design, the EZ Test compact table-top tester, boasts ease-of-use and highly efficient testing, and the UH-X/FX series hydraulic universal testing machine, designed to be both user-friendly and highly effective.

2). Thwing-Albert:

To increase versatility and meet a variety of industry specifications and requirements, they supply a full line of additional tensile test machine grips and fixtures. Additionally, we can provide unique fixtures and grips for a range of testing purposes.

The MAP4TMsoftware is also capable of testing for features like bursting strength, puncture resistance, compression, and peel strength. Thwing-Albert offers a collection of test procedures based on important industry standards including ASTM, ISO, TAPPI, and others. Additionally, MAP4TM gives the user all the resources required to develop unique test methodologies depending on their particular requirements.

This software comes with free technical support for a full year and is compatible with Windows operating systems. call at 856-767-1000:

When holding samples during tensile testing, some of their offered options include:

- Pneumatic grips

- Mechanical vise grips

- Mechanical wedge action grips

- Pincer grips

- COF fixtures

- Peel fixtures

Thwing-Albert provides the following tools for testing tensile strength:

- QC-3A Universal Testing Machine:

- VantageNX Tensile Testing Machines

3). AMETEK STC:

For evaluating the tensile strength of a variety of materials, including plastic, rubber, paper, cloth, yarn, and wire, AMETEK STC offers specialized tensile testers. Our selection of tensile testers is available in a variety of force levels and price points to fit your specific needs and the standards of your quality control.

Their selection of high-precision tensile testers includes digital, motorized, and manual tensile tester equipment for every type of tensile testing up to 150 kN, as well as force gauges.

A specialized library of pre-programmed tensile test configurations is included with their digital tensile testers. Test results can be easily exported to Excel or RS232 using sophisticated analysis software, which presents test findings as easy-to-read graphs.

The tensile testing solution that suits your needs:

- DF Series – See Digital Force Gauges for Tensile Testing

- LG – See Mechanical Force Gauges for Tensile Testing

- Erichsen – See Hydraulic Force Gauges for Tensile Testing

- DG – See Mechanical Force Gauges for Tensile Testing

- MT – See Manual Tensile Testers

- TCM – See Motorized Tensile Testers

- CS – See Digital Tensile Testers up to 5kN

- LS – See Digital Tensile Testers up to 5kN

- LD – See Digital Tensile Testers up to 100 kN

4). TensileMill CNC Inc:

Although TensileMill CNC Inc. is known across the world for producing tensile specimen preparation machines, you’ll be happy to know that we can also give you tensile testing equipment that complies with the most recent international industry standards. They accomplish this by working together with global and American business titans that manufacture tensile testing equipment.

They carefully choose their respected partners depending on how well they reflect our ideals. These ideas include providing the best possible client experience, offering solutions that are simple to use, effective, and affordable, and providing outstanding technical support after the sale to keep your projects moving forward without hiccups.

Together, they offer years of practical experience as well as practical expertise in the best techniques for preparing samples for testing and analyzing materials used in the business. All of this lays the groundwork for supplying reliable tensile testing equipment to end users.

5). The ZwickRoell Group:

Machines for testing materials are available from ZwickRoell. In the world of static materials testing equipment, they are industry leaders. For decades, we have successfully offered solutions for fatigue testing systems in the field of dynamic testing. Additionally, they provide cutting-edge BUP sheet metal testing equipment, hardness testing tools, extrusion plastomes for calculating melt index, and impact testing items.

More than 20 industries use their machines for quality control, research, and development. The professionals can satisfy your specific testing demands with cutting-edge solutions since they have a thorough awareness of the unique requirements of the many sectors.

FAQs

What is Tensile Strength?

The stress under which a material breaks or permanently deforms is known as tensile strength. Tensile strength, yield strength, ultimate strength, and breaking strength are all defined in three different ways. Wire, strip, or machined samples with a circular or rectangular cross-section are frequently subjected to tensile tests.

If the true cross section is measured during the test, the actual stress and strain may occasionally be estimated.

How Do I Select the Perfect Tensile Tester?

Of course, the sort of testing—tensile, compression, fatigue, etc.—as well as the ASTM or ISO standards for the market your product will join will serve as your guidance. When choosing the ideal tensile tester, you should also take the following into account:

Maximum Speed– By examining the machine’s specs for motor speeds, actuator performance, and drive horsepower, one can establish the pace at which the system operates.

Maximum Load: The machine size and whether a tabletop model is an option or whether a free-standing, floor model is necessary for your testing will depend on the maximum load that must be tested on your material.

How Do I Prepare the Perfect Tensile Specimen?

When producers sought information on a certain material’s properties in the past, they had to prepare their raw specimen batches of material and send them to a specialized testing center. The materials would next be milled to make tensile specimens at these facilities, which would subsequently be tested on tensile testers to determine the properties of the materials.

A low-cost, industrial-grade tensile sample preparation machine may now be used to quickly and accurately create the ideal tensile specimen. There are manufacturing wholesalers who offer specified tensile specimen preparation equipment to be employed in-house if you have a big test volume or want more control in creating test samples.

How Do I Perform the Perfect Tensile Test?

Tensile testing involves applying a regulated amount of tension to the sample until a failure happens. Other material characteristics may also be discovered during this test to aid design or production teams in enhancing a product or component.

Engineering calculations can be used to derive other analytical properties by measuring direct qualities like breaking strength, reduction in area, maximum elongation, and ultimate tensile strength of the material.

A specimen with wide, graspable shoulders and a gauge section is typically shown in a sample cross-section. The controlled deformation and failure test is carried out on the smaller gauge part.

Either a square or a round gauge cross-section is used to prepare the specimens. The shoulder regions must be roomy enough to allow the testing fixture to firmly grasp them. This gauge length may differ in relation to the specimen diameter or cross-sectional area, as well as depending on the standard specifications followed or the country ISO standards being used.

What are the Tensile Testing Machine Prices?

Tensile test equipment can cost between $8,700 to $166,000 in 2023. Force capacity has the most influence on the cost of the three key variables—force, test space, and controller.

At Alibaba, there is computerized Control Electronic Universal Compressive Tensile Testing Lab Equipment 100kN ETM-100kN priced: at 1 to 2 Sets-$6,100.00

What is Tensile Testing Procedure?

A tensile tester sometimes referred to as a pull tester or a universal testing machine (UTM), is an electromechanical test equipment that exerts a tensile (pull) force on a substance in order to assess its tensile strength and deformation behavior till break.

Tensile testing machine- tensile test machine – tensile test machine grips – tensile strength testing machine – tensile tester machine – what machine is used for tensile testing – tensile machine – tensile testing equipment – tensile testers- tensile testing machine name